ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

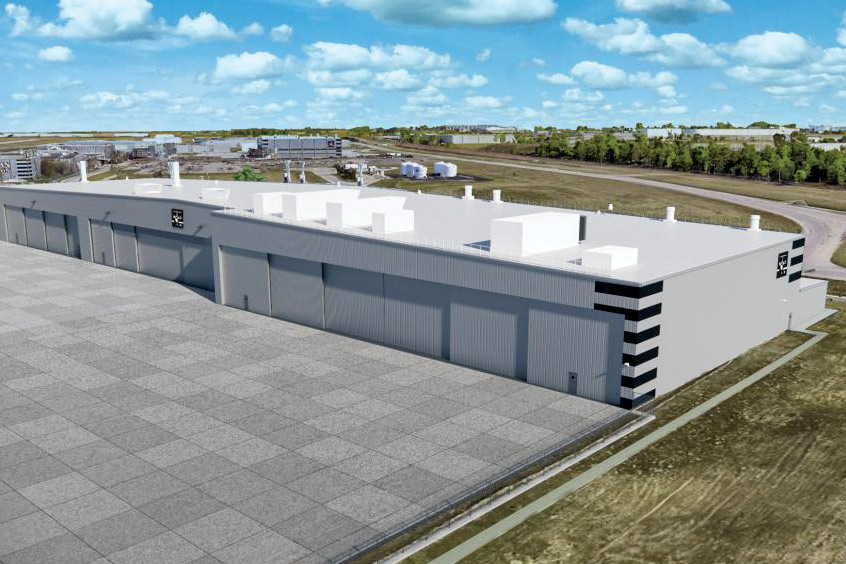

In December, Duncan Aviation is to begin construction of a $25 million paint facility at its Lincoln, Nebraska MRO location.

The greenfield hangar build will include a new 32,500 square foot, dual-bay paint hangar with an adjacent 9,000 square foot storage and support area. The building will connect directly to Duncan Aviation's existing paint facility, built in 2012, and will include expansion of the ramp area on the building's west side.

The cross-draft bays will feature modern climate control, and the facility will expand and upgrade waste water treatment for the entire paint complex, add air showers to contain even more contaminants and provide a small application booth for send-in parts like flaps and thrust-reversers. Hangar lighting will be dimmable so the facility can adapt to changes as future layout and projection equipment becomes an option in Duncan Aviation processes. The facility will also be more energy-efficient, recirculating up to 80 per cent of the heat in any curing processes. In addition, the interior hangar panels and ceiling will be stark white, allowing for better colour quality control during paint application.

Footings for the building will be poured and steel will begin arriving on-site in December. Construction is expected to be complete by January 2026.

“The driving factor for the hangar build is flexibility, not capacity,” says enterprise paint manager Doug Bohac. The Duncan Aviation facility in Lincoln paints roughly 105 aircraft each year, and the company paints 250 aircraft enterprise-wide, which includes those painted at its Battle Creek, Michigan and Provo, Utah MROs. “We won't be painting more aircraft in Lincoln. However, we will be able to offer clients better flexibility, especially those who want detailed, more intricate paint schemes that require more than one paint slot to complete.”

Bohac says the new facility will allow Duncan Aviation to support customers as they move into aircraft models as large as the Gulfstream G650, Falcon 10X and Global 7500. It will also allow more flexibility to support unscheduled and drop-in work like paint touch-up, registration number changes and other paint needs with short lead times.

Once the facility is open, Duncan Aviation will decommission paint bays 1 and 2, which were built in 1990, and repurpose that space to support the overall needs of the organisation. The 45,000 square foot paint facility built in Lincoln in 2012 will continue to serve customers for many years to come.