ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

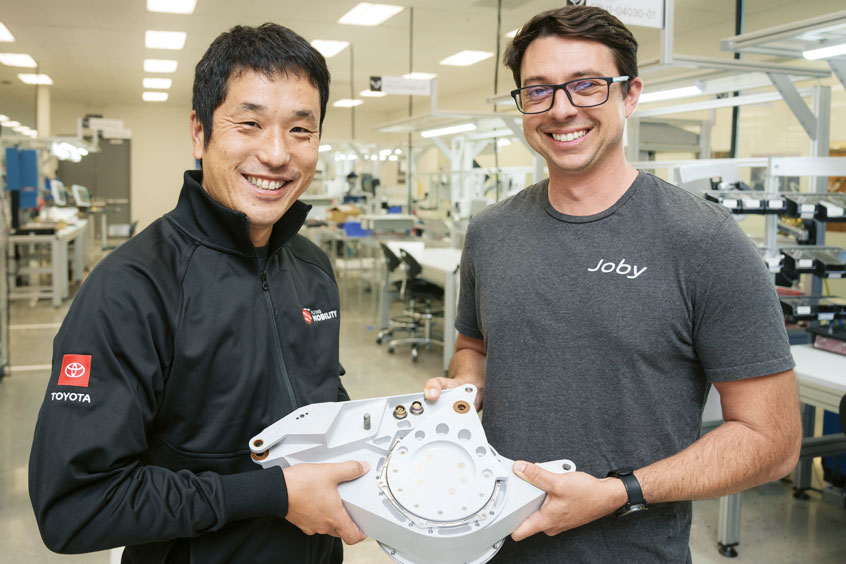

Toyota Motor Corporation is to supply key powertrain and actuation components for the production of Joby Aviation's aircraft.

The long-term agreement builds on the existing partnership between Joby and Toyota, that has seen the two companies collaborate on a wide variety of projects to support the production and assembly of the Joby aircraft, including advising on the design of Joby's pilot production line in Marina, California. Toyota is also Joby's largest external shareholder, having invested around $400 million in the company.

Joby founder and CEO JoeBen Bevirt says: “Our partnership with Toyota continues to be an integral part of Joby's success, from assisting in the design of our pilot production line in Marina, California to supplying key components for our aircraft. I'm grateful for Toyota's unwavering dedication to Joby as we work together to deliver a new form of fast, quiet and emissions-free mobility for cities and communities around the world. Its expertise and knowledge have helped put us on track to deliver, at scale, an aircraft that we believe is truly best-in-class.”

The components, designed by Joby and manufactured by Toyota, will be delivered to Joby's powertrain and electronics manufacturing facility in San Carlos, California before the finished assemblies are shipped to the company's pilot production line in Marina for integration. Intended to prove out scalable tooling and processes at low volumes in advance of aircraft production at full scale, Joby's Marina facilities were designed with Toyota's help, leveraging decades of experience in delivering reliable, high-quality cars at high volume.

Toyota connected company president Keiji Yamamoto adds: “We are very pleased to have reached this milestone with our key partner. Our mutual goal is mass production of eVTOLs and helping Joby apply the best practices of the Toyota production system in meeting high quality, reliability, safety and strict cost standards. We are excited about the potential for further collaboration as we seek to realise Mobility for All with a seamlessly integrated air-to-ground mobility network.”

Joby is working with Toyota subsidiary Aero Asahi on an air taxi shuttle service for Toyota-related passengers in Japan. Joby recently made a formal application to the Japan Civil Aviation Bureau (JCAB) to validate its planned Federal Aviation Administration (FAA) aircraft type certification.