ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

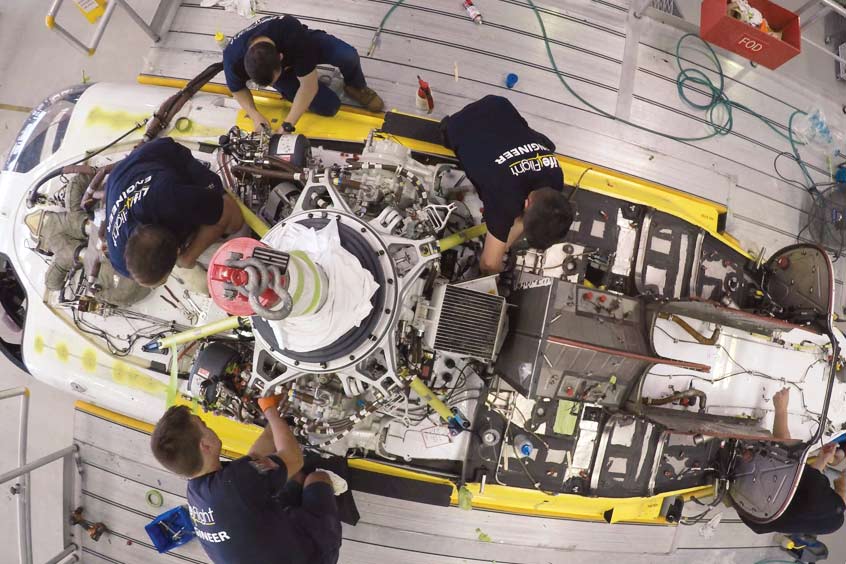

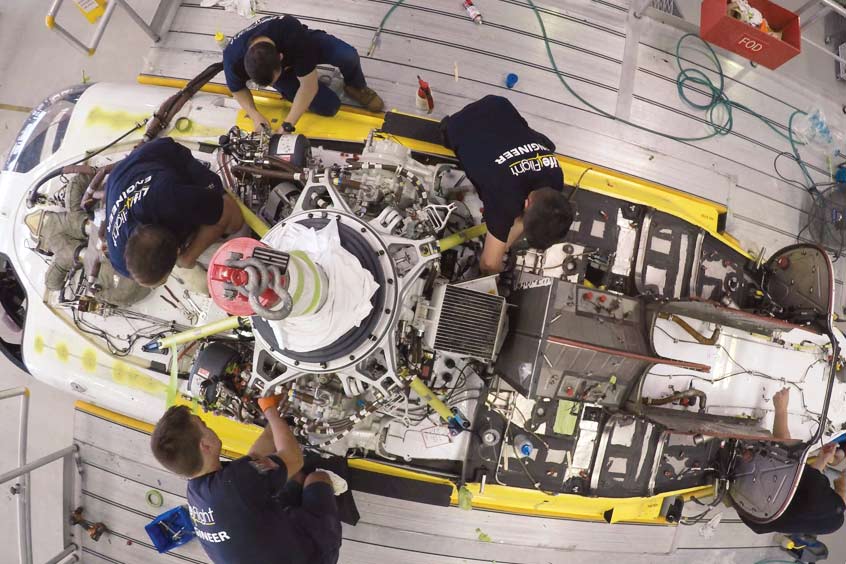

Three of Australia-based LifeFlight's Leonardo AW139 helicopters have undergone complete service ‘pull-downs’ this year after reaching four years of service. Due to the high volume of missions RACQ LifeFlight Rescue helicopters complete, this project coincided with the 2,400 flying hours service of the rotorcraft.

“A lot of places don't work on their own AW139s in house; they outsource it. But we're one of the few that actually do it ourselves,” says engineering operations manager Michael Dopking. “Very few engineers get the opportunity to do this type of work where you see them pull the whole thing down to nothing.”

A hangar at Archerfield airport in Brisbane is home to LifeFlight's heavy maintenance base; this is where the company's engineers work around the clock, to ensure every aircraft is ready to take flight at a moment's notice.

“Here at LifeFlight, we have a real culture and work hard at developing a good work culture,” Dopking continues. “We very actively train our guys from day one, and we're developing them up to become managers.”

Pete De Marzi, executive manager of engineering, talks through a pull-down. “Every component, every nut, bolt and wire is checked and, if necessary, repaired or replaced. Along the way, we set milestones for ourselves and while we aim to achieve those on time, the biggest thing is to make sure we do the job right and at a good quality.”

The project takes around eight weeks and an estimated 4,000 hours to complete. Services of this standard can cost upward of $1 million. Leonardo is already prepared for issues that may arise, as a result of wear and tear. “Leonardo has structural repair manuals, so we go to the book first and if the specific repair is in there, we follow the book. If it's not, we go through our technical services department, tell them the problem we have and they will come back with a specific repair for that aircraft,” De Marzi adds.

In an effort to limit human contact during the COVID-19 pandemic, engineering staff were split into teams and even re-deployed to other bases, but Dopking says the workflow was never interrupted.

RACQ LifeFlight Rescue's fleet is made up of ten helicopters, comprising five AW139s, three Bell 412s, one BK117 and one AS350, and four Bombardier Challenger 604 fixed wing aircraft.

“We are keen to make sure everyone knows everything, to the point where we rotate our engineers from the heavy maintenance base, out to our other bases across Queensland, so that they get a taste of what to expect beyond the line and understand the contract,” De Marzi concludes. “The opportunities and experience we offer our guys are far superior to anything available elsewhere.”