Pratt & Whitney has been celebrating the launch of the new PC-12 NGX aircraft along with Pilatus and Honeywell. The aircraft is powered by P&W's new PT6 E-Series engine, the first turboprop engine in general aviation to offer a dual-channel integrated electronic propeller and engine control system. The company is also enhancing its new Eagle Service Plan (ESP) for the PT6 E-Series engine.

P&W Canada president Maria Della Posta says: “We have injected into this new engine the knowledge that we have acquired over nearly a century of innovation and more than 1.5 billion hours of operational expertise to provide in flying and in customer service. We are proud to say that general aviation's number one engine just got even better.”

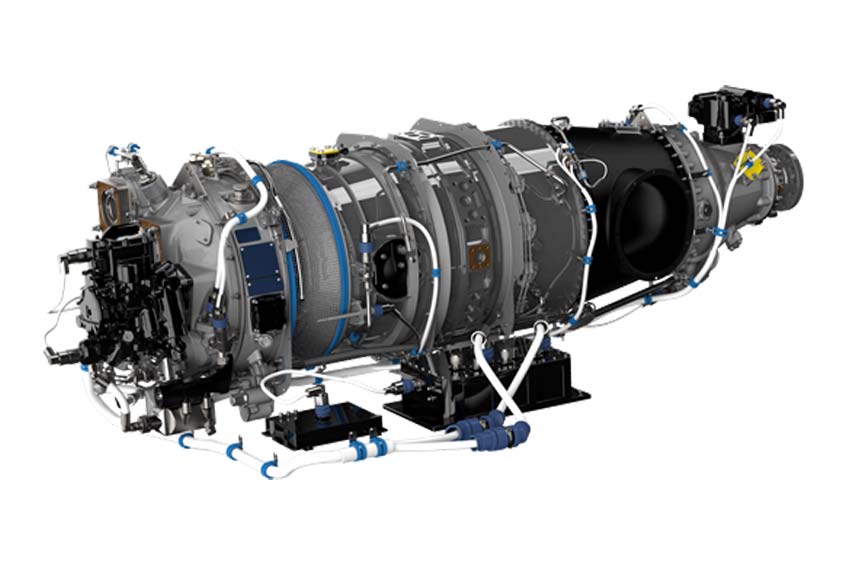

The technology behind the engine is said to provide a more intuitive way of flying with simplified operations. At the push of a button, the pilot can start and stop the engine while being protected against hot and hung starts. The single lever and integrated electronic propeller and engine control system allow precise engine control by constantly monitoring temperature and torque to provide optimal engine power and performance throughout all phases of flight. The new turbine design of the PT6E-67XP engine allows for quicker climb, greater speed and a 10 per cent increase in power to reach the destination faster.

Since the engine is digitally connected, more than 100 parameters are monitored to allow for predictive analysis of the engine and system operation as well as proactive maintenance planning. As the electronic engine control receives all engine and key aircraft data, it is able to make adjustments to optimise and deliver the right engine power needed throughout the flight.

Once the aircraft lands, all the engine flight data is wirelessly downloaded, providing operators and maintainers with valuable new insights into the performance and health of the engine. This allows advanced planning of any maintenance needs, so that customers can maximise their operations and reduce their costs; flying when they need to and for longer periods. Insights gained through the new data maximise the already high, designed-in engine availability - the 600 hour maintenance interval has been increased from 300 hours, and a 43 per cent longer time between overhaul (TBO) intervals increases to 5,000 hours.

The Eagle Service Plan for the PT6 E-Series engine, transferrable at aircraft sale, has been designed so that owners can benefit from a reduction of at least 15 per cent in hourly engine operating costs. It offers a comprehensive coverage plan, including foreign object damage repair and environmental protection, and includes overhaul, scheduled line maintenance, fuel nozzle refurbishment, unscheduled hot section inspection, basic unscheduled repair, accessory repair and more.

ESP customers benefit from the engine's digital connectivity: owners, pilots and maintainers have access to the engine's performance data, which will be sent for trend monitoring and, if required, for troubleshooting. Armed with this information, Pratt & Whitney's predictive analytics team, dedicated engineers and data analysts will provide personalised, high-tech proactive recommendations to equip customers and maintainers with new insights about their engine and the latest technical information to maximise the engine's time on wing and reduce operating costs.