ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

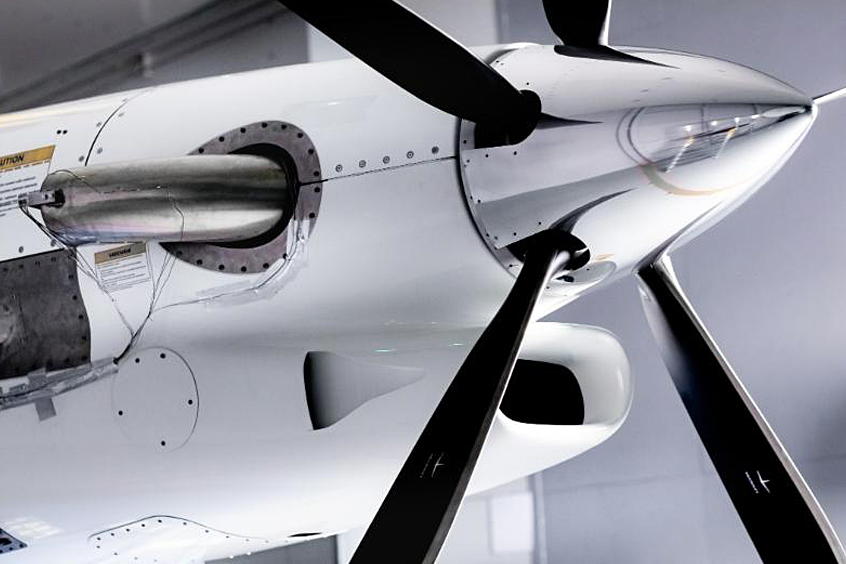

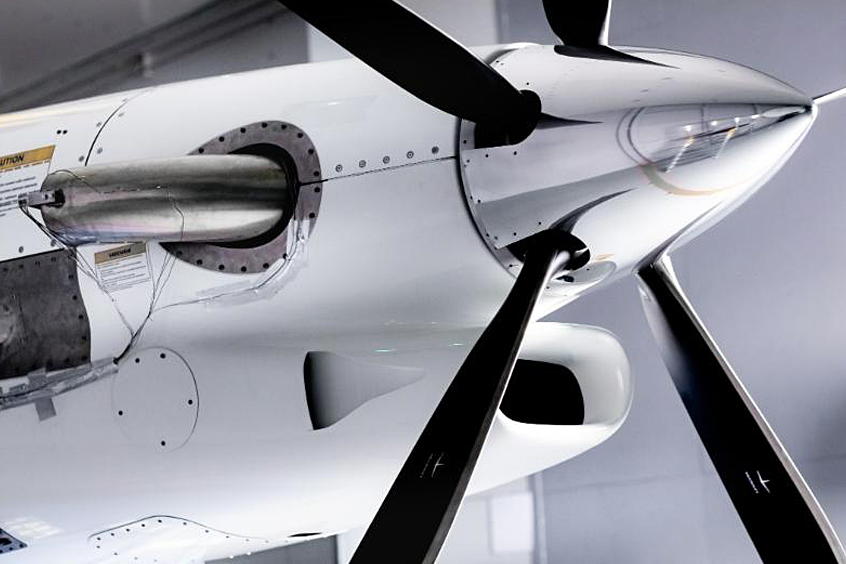

Textron Aviation is nearing completion of the Cessna Denali prototype as well as the first two flight and three ground test articles. “The result of the work we are doing now in design, production and testing is going to provide a mature configuration that will help us move through certification and flight testing, ultimately bringing a proven aircraft to the market,” says senior vice president, engineering Chris Hearne. “The Denali is being designed and built to outperform the competition in capability, pilot interface, cabin experience and total ownership costs.”

The prototype and the first two production conforming aircraft will be used in the flight test programme set to begin later this year, where the three ground test articles will be used for the company's airframe static and fatigue tests, and for cabin interior development and testing.

In preparation for first flight, the company also recently completed component integration for the Denali iron bird, a full systems simulator test rig laid out in the configuration and size of the Denali. Leveraging unique Textron Aviation engineering and manufacturing techniques, the test rig incorporates the design of the aircraft's avionics, electrical and engine control systems, then positions them in a framework that makes the systems easy to access during testing. The iron bird will play an important role in testing the Denali's Full Authority Digital Engine Control (FADEC), which controls both engine power and propeller pitch with a single lever.

Additionally, GE Aviation has successfully achieved full power and max rpm with the new 1300 shp Catalyst engine and the state-of-the-art 105-inch, McCauley composite propeller at its facility in Prague. The engine and propeller demonstrated the full range of pitch using a FADEC with integrated propeller control. Initial altitude chamber testing was completed this month validating the engine performance.

“This engine is modernising the cockpit and flight controls like no other engine has done in this marketplace,” says GE Aviation business and general aviation and integrated systems vice president and general manager Brad Mottier. “The FADEC with integrated propeller control dramatically simplifies the workload in the cockpit, offering a single-control, jet-like experience. It controls propeller pitch, speed and torque. It automatically adjusts and optimises fuel flow and propeller pitch across the entire flight profile. This technology keeps the engine in a safe state, so the pilot doesn't have to worry about overtorquing or overtemping the engine.”

Since the first Catalyst engine start in December 2017, GE's test fleet of engines has racked up enough hours and cycles to simulate more than three years of operations in the field. Initial testing up to 41,000 ft in an altitude chamber was completed in May, validating performance and operability. Tests included chops, bursts and bodies at different points in the envelope, cold-soak starts and auto relight capability.

“This new turboprop engine design will give the Denali a number of key advantages over other aircraft in this class and we are pleased to say that test engine performance is meeting or exceeding performance expectations,” adds Hearne. “New technology allows for a much longer time between overhaul, quieter operation and because of the first-ever digital engine and propeller control, it will reduce pilot workload and have greater fuel efficiency than similar aircraft in its class.”

Featuring the largest flat floor cabin in its segment, Denali's design easily converts between passenger and cargo configurations. The executive seating configuration accommodates six individual reclining seats, club-configuration tables and a refreshment unit, while the commuter seating layout offers nine forward-facing seats. Additionally, the aircraft boasts a digital pressurisation system maintaining a class-leading 6,130 ft cabin altitude at a service ceiling of 31,000 ft.

GE's Catalyst currently has 98 patented technologies on the engine. It is the first turboprop engine in its class to introduce two stages of variable stator vanes, cooled high-pressure turbine blades and 3-D printed parts. It performs at an industry-best 16:1 overall pressure ratio, enabling the engine to achieve 10 per cent higher cruise power compared to competitor offerings in the same size class.

When installed on the Denali, these engine efficiencies help enable a larger cabin experience with a range of 1,600 nm carrying one pilot and four passengers and a comfortable 6,000 ft cabin altitude at a 31,000 ft maximum cruising altitude.

Five GE Catalyst engines have been assembled, with another five engines scheduled to be completed in the second half of this year for certification testing.

“We're going to do a lot of engineering and certification testing the rest of the year,” says GE Aviation Turboprops general manager Paul Corkery. “By the end of the year, we're going to finish and fly our King Air flying test bed which is being constructed in Germany and will be tested in Prague. We are going to retrofit one of the engines out and put in a Catalyst test engine. We'll complete around 75 hours of flight testing starting in the fall of this year.”

GE Aviation has committed more than $400 million in development costs for the programme since the engine was launched in 2015.