ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

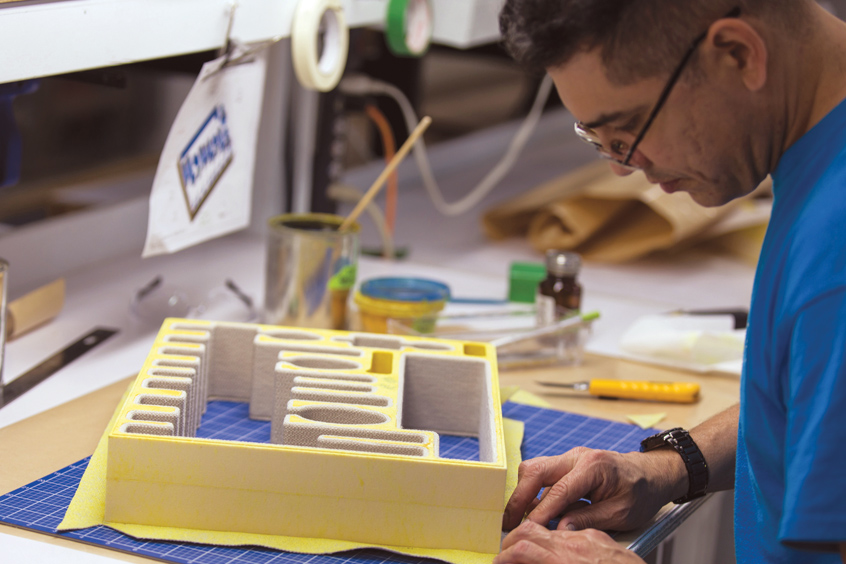

MSB Aerospace has completed and delivered its first set of crystal, china and flatware inserts for Waco, Texas-based L3 Integrated Aerospace Systems. The ninety-piece collection of custom-made inserts is the largest yet sourced from MSB's production facility in Savannah and is destined for installation on a head-of-state aircraft. This represents the first completed project in an ongoing collaboration between L3 Technologies' VIP completions business area and MSB Aerospace.

The custom-made inserts, that were specified in conjunction with L3 completion centre technicians, will safeguard valuable crystal, china and flatware through all phases of flight. In addition, with so many inserts needed, the customer requested a system that enabled access to all the inserts, and their contents, with minimal noise and maximum ease. To facilitate the request, each item features a bespoke MSB-designed handle which supports easy insert egress and access.

The executive airliner cabin incorporated numerous bespoke cabinets in the galley which meant MSB had to aggregate two distinct sets of measurements to fulfil the insert order. MSB accurately measured each of the customised monuments to produce correctly fitting inserts for each space. In addition, a representative selection of each of the tableware items, that had also been custom-made, required meticulous measuring to generate precise template cutouts that were used to produce the protective inserts.

Consideration was also given to where the items will be used in the cabin, the frequency of use and where they will be placed in the cabinets. Form, function and practicality informed the final insert layout blueprint. To meet the strict weight parameters and aviation regulations the inserts were made of a lightweight but strong high-density foam fully certified for aviation use. The physical manufacturing of the complete set took the US-based team just twelve weeks from start to finish.

“This is the largest consignment we've had to fulfil since our doors opened in Savannah in January,” says business development manager Robert Lodge. “There is no doubt that closer proximity to the client, the procurement of materials sourced in the USA and the skills of our local US technical team supported the seamless operational success of this project.”

L3 Integrated Aerospace Systems vice president of head of state programmes Anthony Cusumano adds: “This initial contract with MSB has worked out well. It is a real benefit to us, and therefore our customers, to have a US-based company that understands and fulfils our very exacting requirements.”