ACE 2026 - The home of global charter.

The bimonthly news publication for aviation professionals.

The bimonthly news publication for aviation professionals.

RUAG Australia has earned EASA Part 145 maintenance organisation approval. The certification means that customers operating European-registered commercial and civil aircraft in Australia can now use RUAG's local component MRO services.

With EASA Part 145 certification, RUAG Australia offers component MRO and line support for commercial airline and leasing fleets registered in Europe and operating in Australia. “We excel in the areas of optimised component services, aircraft availability and reduced life cycle costs,” states general manager of operations Terry Miles. “We are now able to apply this considerable experience to benefit operators of private and commercial aircraft that are registered in Europe and flying in Australia, both domestically as well as regionally.”

The EASA Part 145 certification, achieved on the basis of RUAG's Australian Civil Aviation Safety Authority designation, applies to aircraft components including air conditioning and pressurisation systems, engine/APU systems, fuel systems, pneumatic and vacuum systems, and ice/rain/fire protection systems, as well as non-destructive testing, to include fluorescent penetrant inspection and magnetic particle inspection.

“These EASA Part 145 approvals combine with our existing CASA 145 and defence-issued DASA 145 approvals to instil RUAG Australia with an exceptional depth of understanding of the regulations applied by all three bodies, ensuring we deliver accurate and prompt services to all operators, both commercial and defence,” concludes senior VP of international aviation MRO, Stephan Jezler.

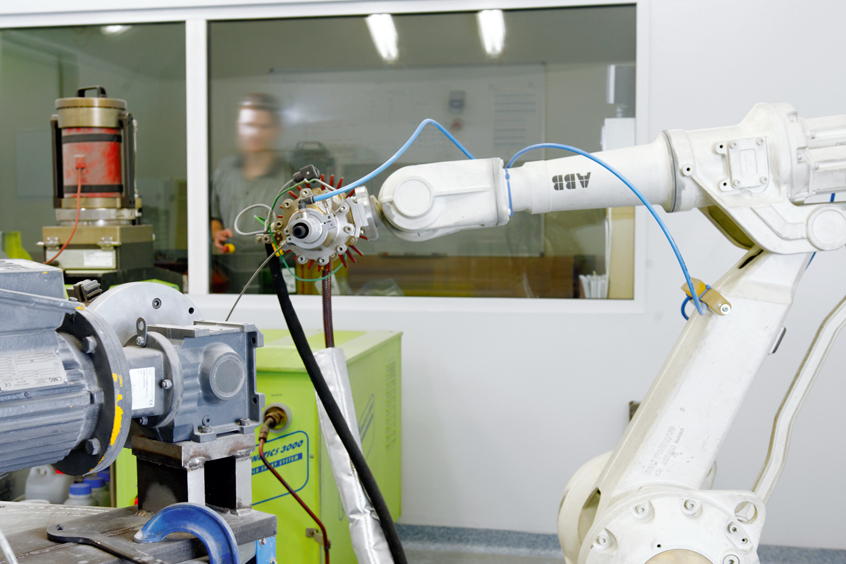

The company has also been awarded full patent rights in Australia, Europe and the United States for its 'Methods for Treating Aircraft Structures'. This patent relates to the use of Supersonic Particle Deposition (SPD) as an alternative aircraft component repair technology to save the time and costs associated with traditional repair techniques or part replacement. SPD repair capabilities significantly improve aircraft and component return-to-service times.

RUAG Australia's patent application identifies the use of SPD additive metal technology as a fully certifiable alternative for safe and reliable repairs. According to the patent, it is an ideal method for rapidly repairing corroded, worn and damaged components as opposed to repair by traditional methods or outright component replacement. Potential cost and time savings make this solution particularly relevant for the repair of expensive components and for components with long repair/replacement lead times.

“The awarding of this patent underscores our commitment to research and development and the application of emerging technologies to offer reliable and accessible service for commercial aviation customers,” says senior manager of advanced technology and engineering solutions Neil Matthews.

Australian, European and US patents for 'Methods for Treating Aircraft Structures' were awarded in May, October and November 2018, respectively. RUAG has also submitted an application for another patent featuring the use of SPD technology, 'Methods for Restoring an Aircraft Frame Element', which is currently under review.

RUAG Australia is a major industry research centre for the development and application of Powder Deposition Technologies focusing on both SPD, sometimes referred to as Cold Spray, and Laser Assisted Deposition (LAD) for defence applications. These technologies offer a number of exciting and cost-effective outcomes, particularly in the areas of geometry restoration and corrosion protection. In addition, these technologies enable the restoration of corroded/damaged metallic components/structures to an acceptable level of structural integrity and functionality. RUAG Australia maintains and operates a fixed and mobile SPD capability as well as a fixed LAD capability.